Ever wondered what the hype surrounding CNC machining benefits was all about? Well, that’s what we’re here to explore in this article.

CNC Machining is highly regarded by individuals and businesses in industries related to fabrication and manufacturing- and this turn of events isn’t difficult to fathom. Gaining wide spread popularity in the 21st century, it has come a long way in the minds of those that use it. Now, it is the forefront fabrication technique used all over the world as we know it. This according to

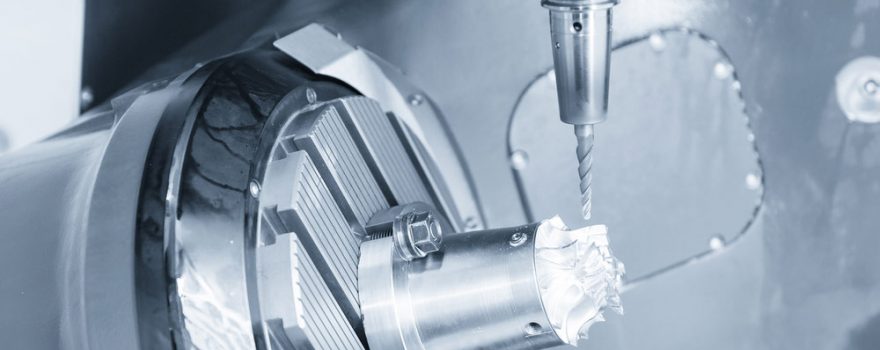

CNC machines come in different shapes and sizes and selection is based on the kind of work to be done (drilling, cutting, molding etc.). Some examples of popularly used CNC machines include drills, lathes, and milling machines. Aside from these, electrical/chemical machining employs techniques like electron beam machining, electrochemical machining, Electrical Discharge Machining (EDM) and more- usually with particular kinds of materials.

In this article, we are going to talk about 10 reasons why people swear by and love Computer Numerical Controlled (or CNC) machining.

Material Versatility: Almost any material can be worked on by a CNC machine. All it depends on is the application for which the finished product is intended. Metals include aluminum, brass, copper, steel, titanium, wood, foam, fiberglass, as well as different plastic materials.

Application in manufacturing and parts industries: A bulk of the applications of CNC machines, software, and personnel are channeled straight towards the manufacturing industries like those for vehicles, trucks, large equipment, heavy machinery, agro implements, and things of the sort. Aside from these of course, spare parts for these same industries also collect a large swathe of the share of raw materials.

Barrier of entry: This advantage leans more towards the businesses that render CNC machining services. There is little barrier to entry into the business outside of the financial ones. If you have industry experience, setting up your own shop is not only possible, it is a viable idea.

Application in manufacturing and parts industries: A bulk of the applications of CNC machines, software, and personnel are channeled straight towards the manufacturing industries like those for vehicles, trucks, large equipment, heavy machinery, agro implements, and things of the sort. Aside from these of course, spare parts for these same industries also collect a large swathe of the share of raw materials. No other method of production serves this industry as well as CNC machining methods.

Fewer mistakes caused by human error: Because there is a less profound human effort requirement with this method, there is a far smaller propensity for human error to affect production.

Consistency and repeatability: Since machines of equal sized and dimensions are used, results are usually consistent across the board. This ensures uniformity.

Precision and accuracy: The level of precision and accuracy that CNC machines possess in processes like boring, drilling, and grinding- are unmatched by human hands and this serves a major advantage.

Fast production: As a result of all the advantaged mentioned previously, CNC services are able to churn out high quality output at a rate that far outstrips conventional means and methods of production. This means that companies can scale their production to accommodate mass market demand.

Reduction of waste: CNC Machining is a parsimonious, highly resource efficient method of production and this means that less input is needed per part than other methods.

Reduction in operator/labour costs: Fewer actual human hands on deck means that labor costs are highly mitigated.

To conclude, there are many advantages to CNC machining over traditional methods. These advantages result in vast gains with regards to turnover times, labor costs, speed, and reliability in production.

Leave a Reply