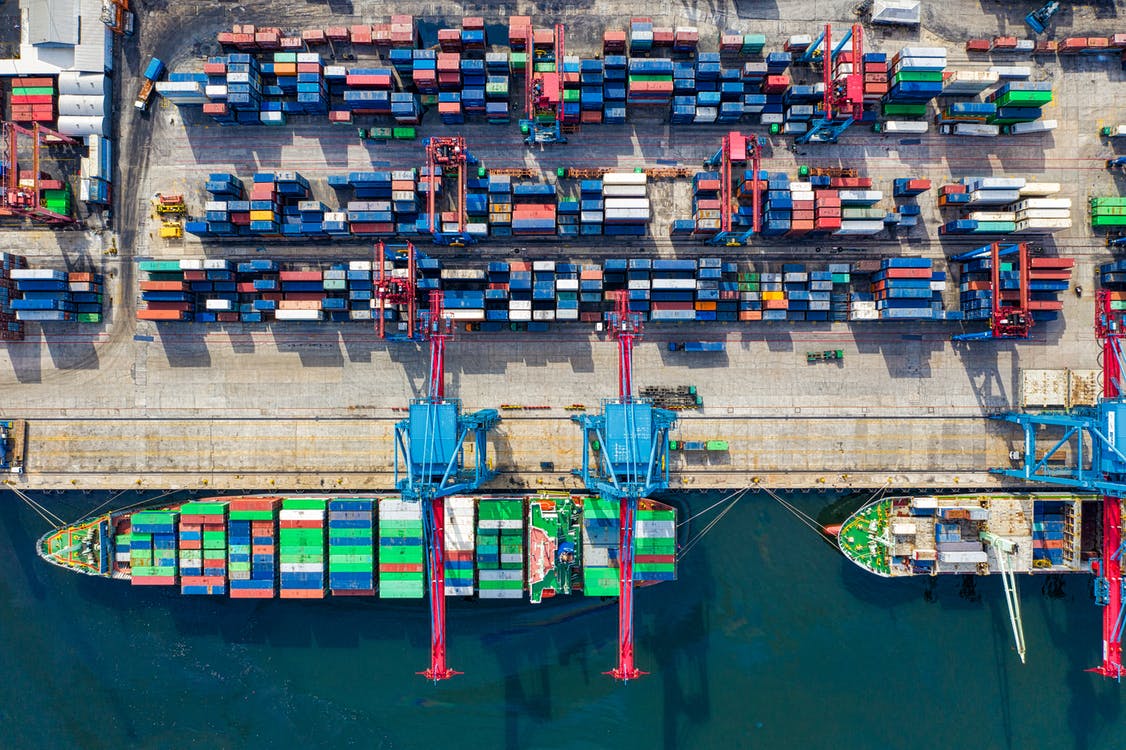

Is your business up and running? Today, global supply chain issues are making headlines worldwide, affecting almost every industry. Some business owners have to procure items locally, whereas others have put their customers on hold. It hinders the smooth flow of business operations, and extended delays have led to immense customer dissatisfaction. After all, the supply chain is a fragile ecosystem that can impact the entire process.

Despite uplifting the travel ban, some countries cannot import raw materials due to government regulations. Similarly, transport failures are another cause of supply chain problems. Regions instituting lockdowns have made it arduous for freight owners to deliver goods timely. So, now the question is how to manage these disruptions?

Even though you won’t notice the upcoming disruptions, you must plan for a potential eventuality. Perhaps, keep a few suppliers and logistics companies in your backup. Likewise, automate the systems to reduce the likelihood of errors. If you want to learn more about this, have a look below. Here we have highlighted five ways for your business to manage supply chain disruptions.

Diversify & Find Alternates

Are you relying on a single vendor? It might sound like an ideal relationship-building tactic but can be harmful to your business in the long run. A significant part of managing supply chain disruption is having backup suppliers and fulfillment companies available. That way, you will have various options if something goes wrong with your primary logistics firm. Hence, look for reliable freight companies like Go Koho within your region.

Having a backup shipping platform ready will allow you to take control, avoiding supply chain problems. However, make sure the freight company offers all three shipment options – sea, air, and road with the best rates. It’ll allow you to send and receive products without any unprecedented delays.

Build Backup Inventory

Do you have inventory in stock? Entrepreneurs think buying extra raw materials will tie up their cash in the working capital. However, that’s not true in every case. Having a few additional items and components in inventory will help your business survive future supply chain disruptions. Hence, whenever you launch a new product or expand operations, consider buying more goods anyway. It will allow you to cater to the demand quickly while reducing dependency on suppliers.

Moreover, you have to also stock up on inventory when there is a high likelihood of supply chain disruptions. Such as during winters, logistics often face delays because of heavy snowfalls, roadblocks, and hurricanes. So, it would be wise to purchase all raw materials before October.

Leverage Technology

Dependence on conventional supply chain models is another reason why disruptions arise. Hence, you have to open yourself to tech advancements and automate the processes. Currently, you can deploy supply chain management software. It is used by many businesses that have to engage in cross-border trade. The software will allow you to manage shipping and track inventory. In turn, you can stay updated and check the status of your inventory from time to time.

Furthermore, leveraging technology can improve collaboration between supply chain partners. Manufacturers can track activities with visibility into the supplier end and the distribution process. It will allow them to make more informed decisions and forecast demand.

Audit Vulnerabilities in Supply Chain

Another part of managing any supply chain problem is creating a contingency plan. That involves auditing the entire supply chain process and pointing out vulnerabilities in the system. You can begin the audit by outlining the cruciality of each point of the supply chain function. For instance, let’s say you run an automobile company and import all of the parts from one country. That point of your supply chain is vulnerable since you don’t have a backup available.

Besides highlighting vulnerabilities, identify the ‘high-risk’ areas. Maybe, you can give a ranking to determine which suppliers are at risk and their importance to your business. You can also dig into their financial history and location to identify the factors that can cause supply chain disruptions. It will help you understand how much it will affect the business and how you can mitigate these problems.

Communicate with Customers

The ongoing supply chain issues are no surprise to anyone. Most customers are also aware that certain items will take longer to ship. Instead of keeping your clients in the dark, be transparent to them. Mention on your website that orders might get delayed due to unforeseen circumstances. Likewise, let people know about the particular products getting delayed before placing orders.

If customers expect something to get delivered in a few days and it doesn’t, it will lead to utmost dissatisfaction. In addition, it can also impact your brand’s credibility. Therefore, you have to keep them in the loop and inform them about delays beforehand to maintain loyalty.

Final Thoughts

Believe it or not, the future of the supply chain also seems uncertain. Political instability in different parts of the world combined with climatic changes will continue to increase disruptions. However, you can always take control of the situation. Get multiple vendors and fulfillment companies on board. Similarly, look into promising tech developments offering creative solutions in the future. It will prepare you for disruptions, helping you respond adequately.

Leave a Reply